Site Wesseling - View to the South | Photo: Site Wesseling-Knapsack presentation (Oct 12, 2023)

LyondellBasell’s Wesseling site (together with the nearby Knapsack site) is the company’s largest manufacturing complex in Europe and functions as an integrated olefins‑to‑polyolefins hub in the Cologne/Rhineland chemical region.

The Wesseling/Knapsack complex comprises two manufacturing sites that operate as a single integrated facility, with Wesseling itself covering more than 2.7 km² and hosting ethylene and propylene plants (steam crackers), multiple PE and PP units, an advanced polyolefins plant, and extensive utilities. Across the two sites, installed capacity exceeds 2.2 million t/y of polyolefins, supported by an on‑site power plant (about 470 MW), wastewater treatment and sewage incineration units, and dedicated logistics centers handling up to roughly 500 kt/y of polymer granulate in bulk and packaged form.

The complex produces ethylene, propylene, butadiene and isobutane as key cracker products and converts these into polyethylene, polypropylene and polypropylene compounds for applications including films, pipe and cable coating, fuel tanks, injection mouldings and household articles. Wesseling is also the focal German site for LyondellBasell’s advanced recycling strategy, including a first industrial‑scale MoReTec‑based catalytic recycling plant and a permitted pyrolysis unit, both targeting feedstock recycling of mixed plastic waste.

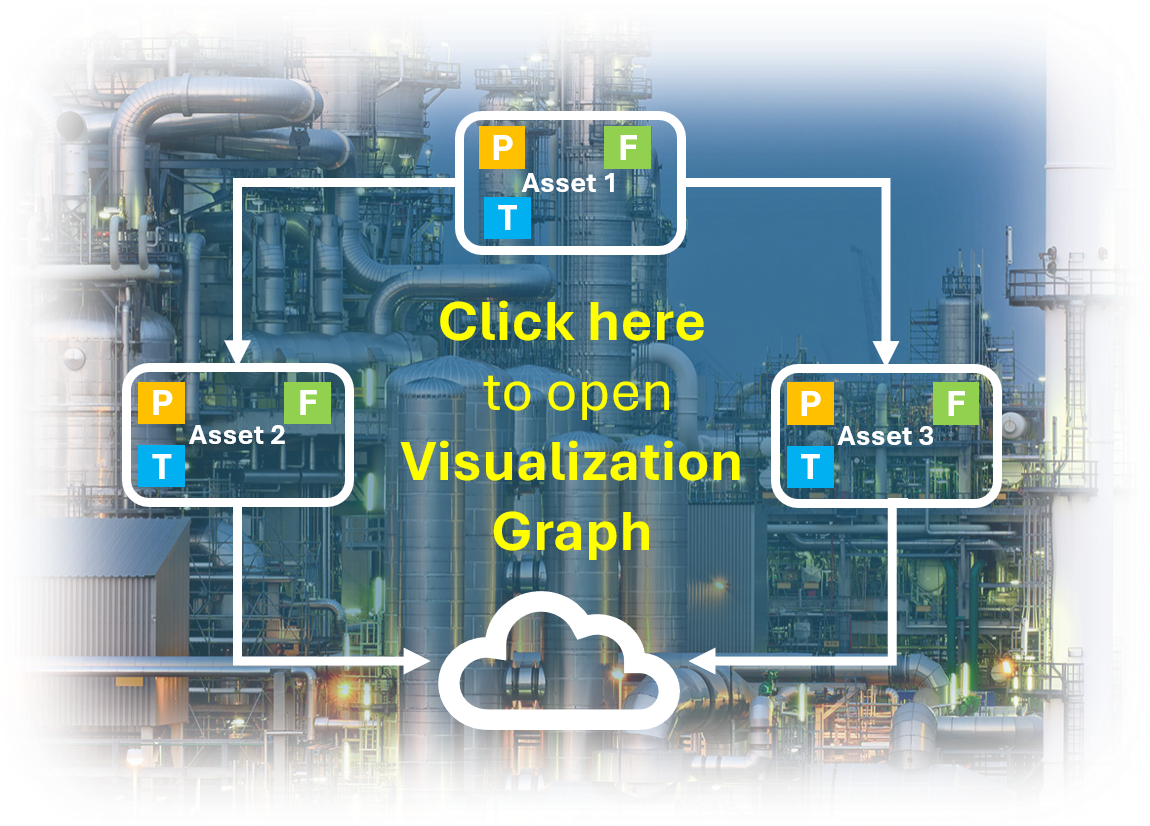

Wesseling-Knapsack Complex Block Flow Diagram | Source: Pipe Customer Event - Site Wesseling-Knapsack Presentation (Oct 12, 2023)