Ordos Facility of Inner Mongolia Baofeng Coal-Based New Materials Co., Ltd. | Credit: sina, 28th Mar 2025

The Inner Mongolia Baofeng Coal-based New Materials facility in Ordos represents the world's largest single-site coal-to-olefins project. With a total investment of RMB 67.3 billion and 3.0 million tonnes/year olefin production capacity, the facility integrates traditional coal gasification with renewable energy technologies, including the world's first commercial-scale deployment of solar and wind-powered green hydrogen directly coupled with coal-to-chemical processes.

Located in the Wushenqi Sulige Economic Development Zone, this 594-hectare complex showcases China's technological leadership in clean coal conversion, achieving what industry experts consider the most advanced and economically viable pathway to carbon-neutral petrochemical production at unprecedented scale. The facility's unique integration of 11 world-class gasifiers, three methanol synthesis trains, three DMTO-III olefin units, and downstream polymerization plants establishes new global benchmarks for both production scale and environmental performance in the coal chemical industry.

Coal Gasification

The site operates 11 units of CECO HT-L high-temperature entrained-flow gasifiers, each with a capacity of 4,000 tonnes/day, organized in three series and processing raw coal feedstock to produce synthesis gas (syngas containing CO and H₂). One news article from March 2023 mentions 3 × 562,000 Nm3/h effective gas (CO+H2) gasification capacity. This represents the world's largest single gasifier capacity configuration.

Green Hydrogen Production

A dedicated renewable energy complex generates green hydrogen through solar and wind-powered electrolysis of water. The project includes the construction of a facility that can produce 2.6 million tons of coal-to-olefins and 400,000 tonnes of green hydrogen coupling olefins annually, i.e. the green hydrogen is directly integrated into the methanol synthesis process, replacing fossil-derived hydrogen for the production of olefins to the extent of 400,000 tonnes per year from a total of 3,000,000 tonnes of olefins annually, which is claimed to reduce CO₂ emissions by 1.4 million tonnes annually while saving 800,000 tons of coal equivalent per year.

Methanol Synthesis

Three methanol production trains, each with a production capacity of 2,200,000 tonnes/year, convert the syngas and green hydrogen into MTO-grade methanol using low-pressure synthesis technology. The combined methanol capacity supports the downstream olefins production, with the world's largest single-train methanol units commissioned between November 2024 and March 2025.

Air Separation Units (ASU)

Six air separation units, each with an oxygen production capacity of 110,000 Nm3/h manufactured by Hangzhou Oxygen Plant Group CO., Ltd., the first of which started up in Oct 2024. A news report from March 2023 mentions that the project includes instead seven instead of six air production units, each producing 110000 Nm3/h oxygen separated from the air for a total of 770,000 Nm3/h of oxygen.

Sulfur Recovery Units

The project includes 3 Sulfur Recovery Units, each with a capacity to produce 65,000 tonnes of sulfur annyally.

Methanol-to-Olefins (MTO)

Three DMTO-III units, each with 1,000,000 tonnes/year capacity, convert methanol feedstock into mixed C₂-C₄ olefins (ethylene, propylene, and butenes). This third-generation technology, developed by Dalian Institute of Chemical Physics and Sinopec, achieves industry-leading methanol consumption efficiency of 2.65 tonnes methanol per ton of olefins. The C4 fraction, containing butenes and other C4 compounds, is processed in downstream units for specialty chemical production.

Olefin Separation and Fractionation

Advanced separation systems process the mixed olefin stream from MTO units to produce polymer-grade ethylene and propylene, along with C4 byproducts for downstream processing. The total site olefin production capacity is 3.0 million tonnes/year (2.6 Mt coal-based + 0.4 Mt green hydrogen-coupled).

Polyethylene Production

Three polyethylene plants utilizing Unipol PE gas-phase fluidized bed technology produce 1.65 million tonnes/year of various PE grades including HDPE and LLDPE. Each unit has approximately 550,000 tonnes/year capacity, processing polymer-grade ethylene into commodity and specialty polyethylene products.

Polypropylene Production

Polypropylene production facilities employ Basell Spheripol liquid-gas phase combined technology to produce 1.5 million tonnes/year of PP products, including homopolymer and copolymer grades for automotive, packaging, and textile applications.

Utilities and Infrastructure

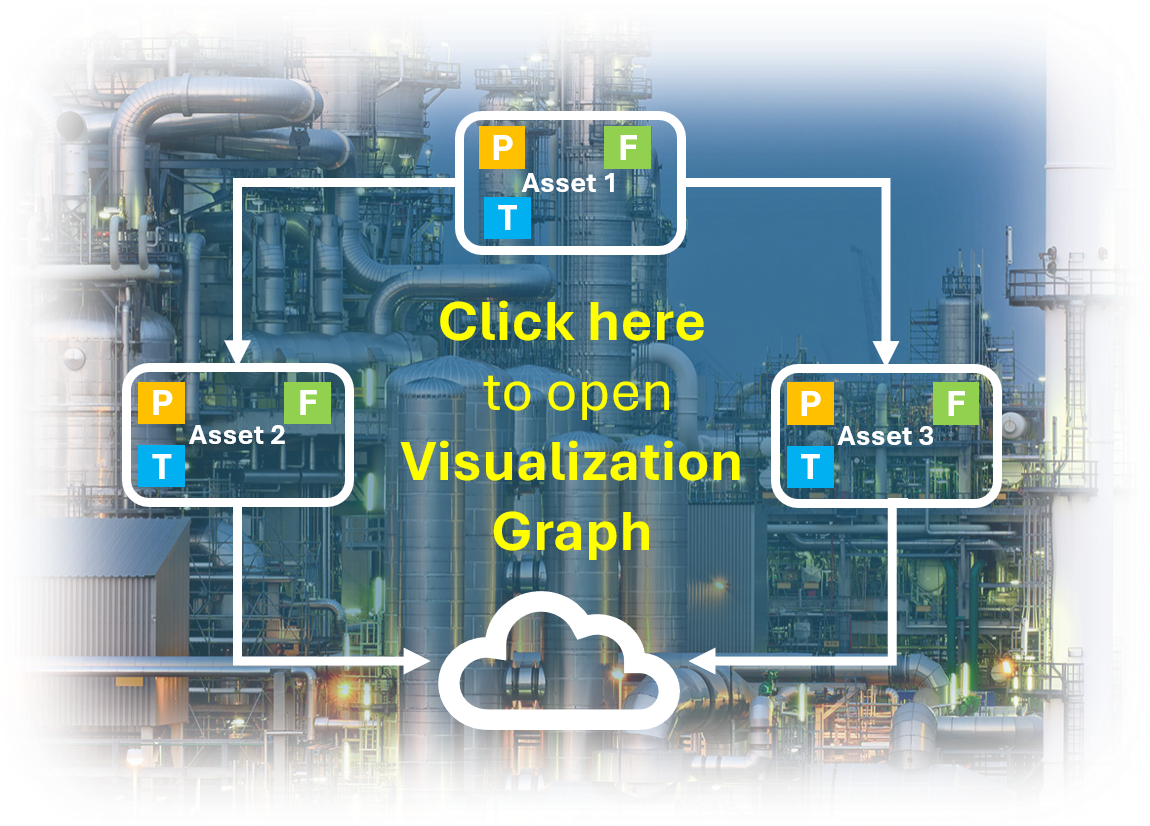

Integrated utilities systems provide steam, power, compressed air, and cooling water to all production units. A centralized control system optimizes material and energy flows across the complex, while waste heat recovery and tail-gas recycling systems maximize resource efficiency and minimize environmental impact.

Participants of the Ordos Ujingqi Baofeng Energy Inner Mongolia Coal-based New Materials Industry Base Conference Center visit the command and control center on June 16, 2025 | Credit: stcn