IRPC Integrated Petroleum and Petrochemical Complex Flow Chart, from Annual Report 2223.

IRPC Production Capacity and Volume (Unit: KTA), from Annual Report 2023.

| Notes |

(1) Total production capacity and volume of products consist of main products and other products.

(2) Volume includes products used as feedstock in the plants.

(3) Olefins production capacity at 696 KTA does not include olefins from DDC and RDCC plants.

(4) In 2022, approximately 37 days of turnaround--scheduled large-scale maintenance activity. |

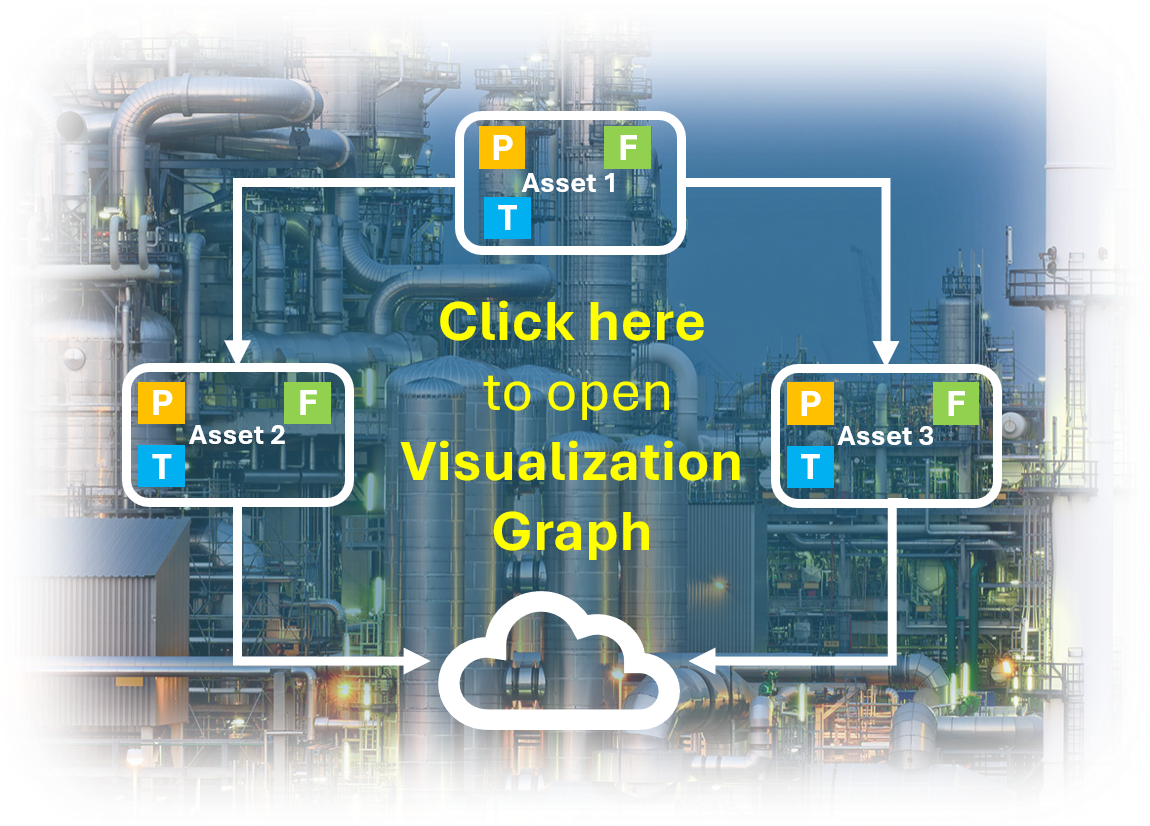

The Company operates a refinery and petrochemical complex in Rayong. Its main facilities are located within the IRPC Industrial Park, which features the infrastructure needed for its business, including a deep-sea port, an oil depot, and a power plant.

Petroleum Business

IRPC’s refinery has a total capacity of 215,000 barrels per day (bpd), the 3rd largest refinery in Thailand in terms of production capacity. IRPC manufactures a range of petroleum products, namely liquefied petroleum gas (LPG), naphtha, gasoline, diesel, and fuel oil. Additionally, IRPC’s Lube Base Oil Group I plant has a total capacity of 320 kilotons per annum (KTA), and the associated asphalt plant has a total capacity of 600 KTA, which are the highest domestic capacities. It is Thailand’s first asphalt plant to sell TIS-certified 40/50 asphalt in the domestic market. IRPC is also a producer of the Terramaxx-branded rubber process oil, whose quality has attained international recognition.

- Gasoline: Under state regulations, IRPC’s gasoline is divided into ULG91 lead-free gasoline, GSH95 and GSH91 gasohol, and gasohol base, the last of which is used to manufacture gasohol and E20.

- Diesel: IRPC offers blends of 5-7% biodiesel as per government policy to promote the use of alternative energy and palm oil. Furthermore, as per government policy, B10 is the standard diesel in Thailand, while B7 and B20 are alternatives. IRPC began selling B20 by mid-2018; and B10 at the end of 2019.

- Fuel oil: A fraction of crude oil with a high boiling point, fuel oil is widely used in the industrial sector, transportation, and power generation.

- Liquified petroleum gas LPG): A mixture of hydrocarbon gases, mainly propane and butane, LPG is commonly found in household kitchens and various other industries. It can also be used as a fuel or gasoline engines.

- Lube base oils: Lube base oils refer to heavy distillates used for producing different grades of lubricants. IRPC produces the following grades of base oil for various purposes and applications: 150 SN, 500 SN, 150 BS. In addition to these products, IRPC has researched and developed base oils such as Treated Distillate Aromatic Extract (TDAE) and Residue Aromatic Extract (RAE).

- Asphalt: Asphalt, also called bitumen, is a compound of hydrocarbons and other organic substances. Thick and viscous, asphalt is the heaviest portion obtained from the crude oil distillation process.

- Naphtha: Naphtha refers to light distillates obtained from the oil refining process. It is a major petrochemical feedstock.

Petrochemical Business

IRPC is a producer of upstream petrochemical products, namely olefins and aromatics. These upstream products are feedstocks for IRPC’s downstream petrochemical plants: 931 KTA of polyolefins (HDPE and PP, UHMW-PE) and 383 KTA of styrenics (ABS, SAN, PS,and EPS). Recent innovations include paralene from natural ingredients, recycled compound resin, and acetylene black for Li- ion batteries (Pim-L and Pim-AL).

- Olefins: Olefin products-namely ethylene, propylene, and butadiene are feedstocks for the production of various polymers, namely polyethylene (PE) and polypropylene (PP). IRPC produces 433 KTA of ethylene, 732 KTA of propylene, and 56 KTA of butadiene. Most of these olefins serve as feedstocks for the various manufacturing plants in the IRPC Group. Furthermore, the olefins plant yields acetylene black as a by-product. IRPC currently produces 4 KTA of acetylene black.

- Aromatics: IRPC’s aromatic products consist of benzene, toluene, and mixed xylenes, with a capacity of 114 KTA, 132 KTA, and 121 tons per year, respectively. They are used as feedstocks for manufacturing plants in IRPC’s subsidiaries and partially sold to other industries.

- Polymers: IRPC and its subsidiaries produce polymer products under the brand POLIMAXX. As downstream petrochemical products, polymers are the feedstock for various plastic products. IRPC manufactures two groups of polymers. The polyolefins group comprises HDPE and PP, while the styrenics group includes ABS, PS, and EPS. Each polymer type possesses distinct properties and lends itself to different applications:

- High Density Polyethylene (HDPE): IRPC’s HDPE is a high-density polyethylene product with in-line compounding.

- Polypropylene (PP): IRPC produces PP Homopolymer, impact-resistant PP Block Copolymer, and extratransparent PP Random Copolymer. It also manufactures PP Compounds.

- Acrylonitrile-Butadiene-Styrene (ABS): IRPC produces many grades of ABS.

- Polystyrene (PS): IRPC produces two categories of PS based on its properties. General Purpose Polystyrene (GPPS) and High Impact Polystyrene.

- Expandable Polystyrene (EPS): IRPC mainly uses styrene monomer as feedstock for its EPS, with pentane as the blowing agent. The Company uses no ozone-depleting CFCs.